What is CNC milling?

That’s a big question, spanning several different topics. Many sources cover the topic of CNC milling, and any one of them could lead you down a rabbit hole of industrial proportions. To keep it simple, in this article, we’ll break CNC milling down in four sections.

First, we’ll discuss the difference between additive and subtractive manufacturing. Then, we’ll explore what a milling machine (often simply called a “mill”) is and compare it to other subtractive manufacturing machines. Next, we’ll briefly cover computer numerical control (CNC) before finally discussing how CNC came to be applied to mills.

We’ll also touch on tools and software, which are important areas for further reading if you want to learn how to get a hands-on experience!

WHAT IS CNC MILLING?

Subtractive Manufacturing

Subtractive manufacturing is the process of removing material to create a finished part. This differs from additive manufacturing, which is the addition of material to create a finished part, such as 3D printing, casting, or injection molding.

Both additive and subtractive techniques work for metal, ceramics, glass, and plastic, but only subtractive can be used for naturally grown wood planks and natural stone. (You can, however, get some interesting results by using composites like wood- or marble-PLA hybrid filaments.)

Subtractive manufacturing has been around since the Stone Age. With contemporary machining emerging around the early 1800s, the process is well understood and provides several advantages. The following are some benefits of using modern subtractive manufacturing methods:

A high degree of control over the surface finish

Low costs relative to part precision

Isotropic strength of finished parts (they’re equally strong in all directions)

Ease of part qualification, particularly for aerospace applications

Readily available tooling

Well-trained fabrication workers

The ability to work with a variety of materials

There are various ways to remove material to achieve a finished part:

Cutting: Using saws, lasers, plasma cutters, etc.

Drilling: Using drills, borers, broaches, etc.

Abrading: Using grinders, sanders, blasters, etc.

Machining: Using any combination of the above methods to achieve high-precision, complex geometries.

So where do mills fit into all of this?

WHAT IS CNC MILLING?

Milling

A mill is one of the two most common types of metal machining tools. The other is a lathe. Mills (usually) move the workpiece slowly while the tool rotates quickly in place. This process differs from lathes, which move the tool slowly while the workpiece rotates quickly in place, making them ideal for creating cylindrical shapes such as driveshafts. The lead screws on your 3D printer were likely machined on a CNC lathe, whereas the metal gears in your extruder are probably the work of a CNC mill.

Without any movement, a mill makes round holes in a material. This hole is then dragged through the material to create cutouts of various shapes. Since the tool can be dragged along any axis, the cutouts can be of almost any three-dimensional shape.

Since most mills are used for metals and most metals are very hard, many shallow cuts, known as passes, are required to bring the desired shape to life. Even flattening one surface of a part may require many passes to achieve the desired flatness. In general, the harder the material, the more passes are required.

While some find this work relaxing, it can be repetitive and slow, making it difficult for many people. Imagine if there was a way to keep the mental challenges and rewards of the finished product without the tedious hours of manually cranking a machine bed!

Enter CNC.

WHAT IS CNC MILLING?

CNC

Computer numerical control (CNC) is the use of programmed code as a set of instructions for precise movements to control manufacturing machines. Indirectly, this code defines how to automatically create, produce, or transform a virtual object into a real one.

Based on this definition, a CNC machine must interact with a computer equipped with software that transforms numerical code into instructions for the machine (usually in terms of Cartesian coordinates). This turns the machine into a robot with an extremely high degree of accuracy.

Depending on its particular design and configuration, a CNC machine takes raw material and transforms it into a finished model. We’ve already mentioned the two methods by which this can be done, additive (adding) and subtractive (removing) manufacturing. The available techniques change depending on the type of machine. A 3D printer is an example of additive CNC manufacturing, and a CNC milling machine is an example of subtractive CNC manufacturing.

So how did CNC come to be, and how is it integrated into milling machines?

WHAT IS CNC MILLING?

Milling Meets CNC

When the milling machine was first developed in 1818, moving the tool through the workpiece was accomplished by turning handles on the machine. These had a vernier scale, which allowed the machinist to measure how far the tool had moved.

Later, this was supplemented by powered feeds that could drive the base at a constant rate along an axis, often using gearing from a spindle motor. Once the technology became available, digital readouts (DROs) visually displayed the location of the tool. Furthermore, it became possible to reverse the process and input digital instructions. Logically, the next step was to automate the input of digital instructions using computers.

Replacing powered feeds with precise numbers from computers meant that these motors were numerically controlled by computers. CNC directly translated the instructions from the DRO into motion. Through computer-aided design, shapes that were previously impossible or impractical, such as precision elliptical radii, could now be manufactured.

The humble Creality Ender 3 printer, sitting in the corner printing a picture frame, owes much of its genetics to CNC mills. The use of open-loop control and even the codes used to instruct printer movements stem from the codes used to control large CNC machines such as CNC mills.

So, if a mill moves a tool through a workpiece, and the path that that tool takes depends on the material and the type of tool, how do we come up with the CNC instructions for the machine?

WHAT IS CNC MILLING?

Tools, Toolpaths & Software

The tool in a mill is the equivalent of the hot end in a 3D printer. It’s the business end.

Mills can take a variety of tools, with the most basic being end mills, which are essentially drill bits that can cut through and sideways. Other types of tools include slot cutters, which look like small circular saw blades; profile cutters, which have a complex shape for creating specific contours; face cutters, which are used to create a smooth and flat face on the part; and fly cutters, which have a tooth on the end of an arm for a very wide radius of cut.

Similar to slicing in 3D printing, special software is used to generate the instructions for the CNC mill to follow. These instructions describe the toolpath, which is, as it sounds, the path that the tool will follow through the workpiece. The best toolpath for the job depends on many factors. Significant training and experience will most likely be required to get the best results in the more challenging materials.

There are loads of software packages available that provide instructions for CNC machines.

WHAT IS CNC MILLING?

Types of Mills

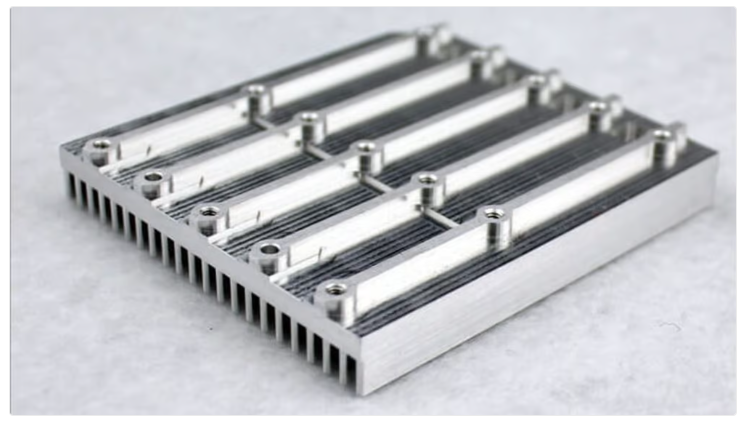

CNC milling creates many of the highest precision parts that humankind is capable of producing. For this reason, you’ll find CNC-milled parts in machines of all kinds, from internal combustion engines to electric motors. The shapes that can be created in a CNC mill enable some of the most elegant solutions to complex engineering problems.

Industrial mills have price tags that would make your eyes water, but you can start on much more affordable machines. While hobby machines are usually significantly less capable, with care and effort, they can create parts that are just as precise as their larger cousins. If you’re looking to dip your toes into CNC machining, we recommend starting with a capable desktop CNC router, which can do most things a mill can.

Classification by Axes

Taking all of the above into account, milling machines have the unique possibility to cut in different angles and move along different axes. For this reason, there are several kinds of milling machines, which are designated by the number of moving axes:

2-axis milling machines can cut holes and slots in the X- and Z-axes. In other words, they will only cut vertically and horizontally, but only along two lines.

3-axis milling machines add the Y-axis. This is the most common variety of milling machine. You can cut vertically and in any direction, but an object like a sphere will need to be done one half at a time. This is because, even with three axes, it’s not possible to cut from below.

4-axis milling machines are more complex because they add the ability to rotate the x-axis, similar to a lathe.

5-axis milling machines incorporate rotation in both the X- and Y-axes. This is the most “complete” milling machine you can have. It allows you to shape bones, aerospace structures, car models, medical products, and pretty much anything else you can imagine.

Classification by Machine

Apart from axis classifications, there are still several types of milling machines, whether manual or CNC:

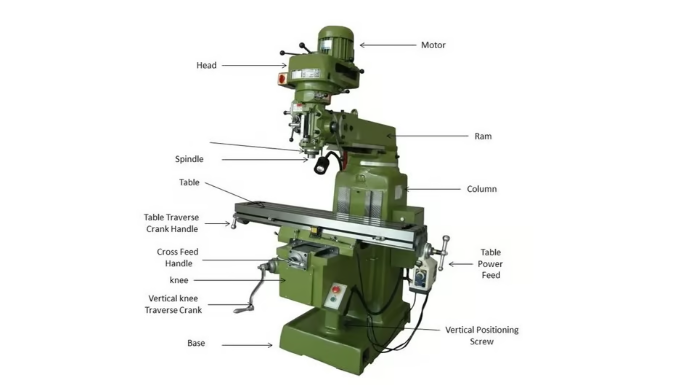

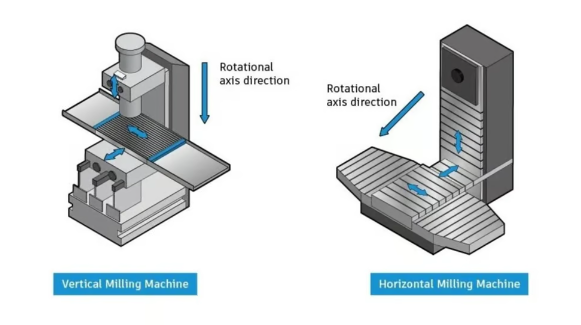

Vertical mill: This 3-axis milling machine consists of a table, which acts as a work surface, below an arm, to which the spindle is attached. Both the table and the arm are connected to a vertical column, and the spindle is vertically oriented. Generally speaking, the table moves up and down along the Z-axis in order to meet the arm, which is fixed. However, how the table and the spindle move in relation to each other depends on the type of vertical mill. In a turret vertical mill, the spindle is stationary and the table moves along both the x- and y-axes. In a bed vertical mill, the table can only be moved along the x-axis, while the spindle can travel along the length of the arm in the y-axis direction.

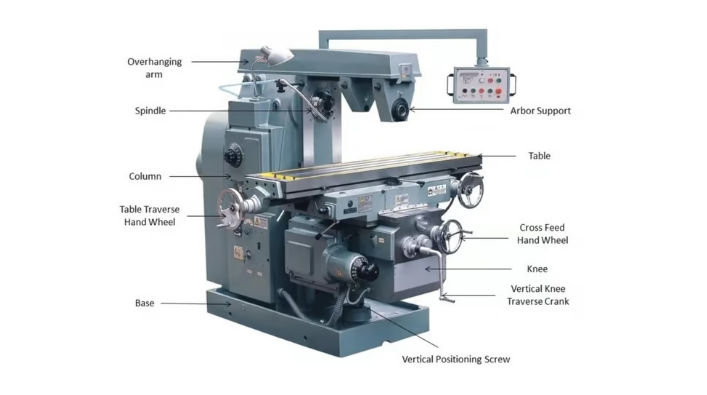

Horizontal mill: This milling machine is similar to a vertical mill, except that the spindle is oriented horizontally instead of vertically. While generally considered less versatile than vertical mills, horizontal mills are better-suited to longer or heavy pieces of work. A universal horizontal mill has the additional capacity to rotate the table around the -axis (making it a 4-axis milling machine).

Knee mill: Any kind of mill where the table moves up and down the column according to an adjustable knee.

WHAT IS CNC MILLING?

The Importance of CNC Milling

Digital technologies and CNC milling machines allow for the resolution of many problems which cannot be easily solved using prior methods. The technology approaches the working process in a way that’s both more effective and more efficient.

For example, without a CNC milling machine, the process of cutting metal for car parts or even aerospace components would be much riskier. With the support of computer programs, one can access and create high-definition designs that are easily converted into Cartesian coordinates. This process even helps lower the costs of prototyping!

But these technological machines aren’t only for industrial use. Other areas include furniture, instruments, and sculpture. There’s also a wide range of (hard and soft) solid materials that a CNC milling machine can cut, including aluminum, titanium, copper, bronze, PVC, nylon, and plywood.

Final Thoughts

There is much to learn about CNC milling or even just milling in general. For example, there are many different types of milling machines, all with different advantages and drawbacks. You might also like to learn about the other types of subtractive manufacturing, such as turning or grinding.